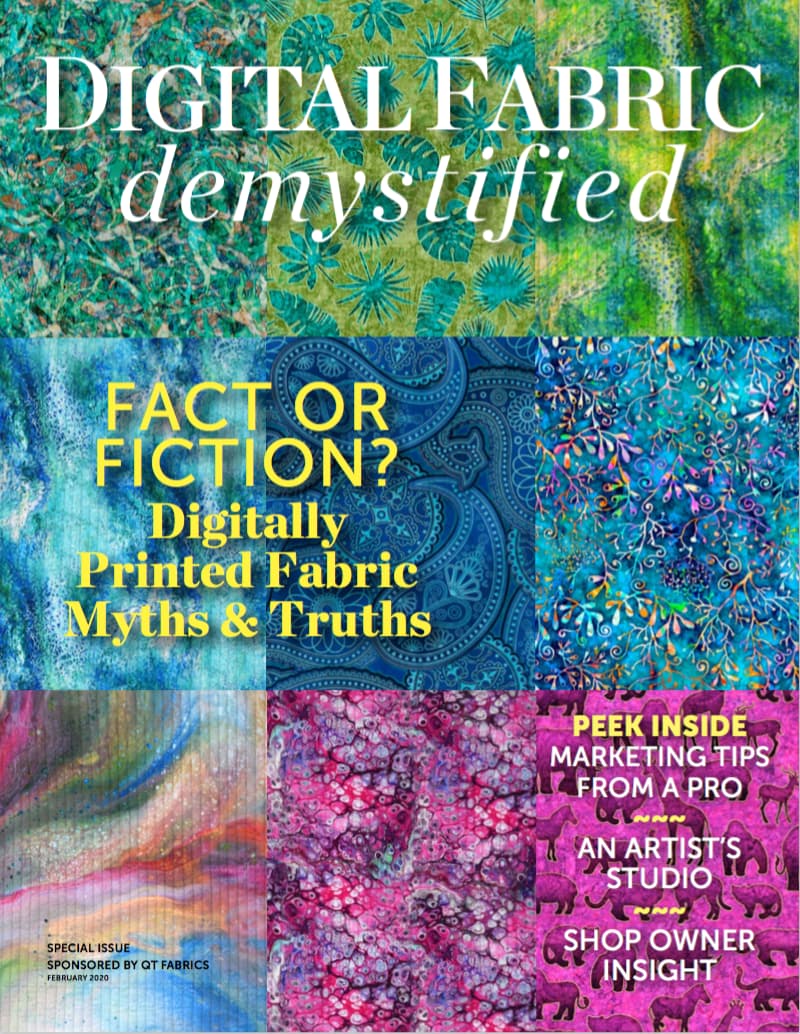

Although brought to you by QT Fabrics, this magazine is not necessarily a QT Fabrics magazine. The purpose is to educate you on the differences, and more importantly, the similarities between flatbed printing and digital printing. We are determined to demonstrate and compare the perception of digital versus the reality.

Technology is ever evolving, impacting our lives for the better. Anyone still have a two-party rotary phone hanging on the wall at home? A black-and-white 12″ television with a roof antenna? Artificial hips, knees, noninvasive surgeries—you get my point. Change is confusion, but mostly good.

I have witnessed many changes in our industry during my 40+ years at QT Fabrics. Including my father and grandfather, there has been a Gamache on the QT payroll since 1940! We mostly worked in our (now closed) factories for a long time, and I personally have had to learn and relearn my profession repeatedly. Change is hard, but fulfilling.

The largest change I can think of is transitioning from screen to digital printed fabric. I can remember when it took four hours to change a copper roller print machine from one design to another design. Now with digital printing it is instantaneous.There was a time we could only print eight color positions on a roller print machine or 18 colors with flatbed printing. Now with digital printing we have almost unlimited color options. Currently, it takes 15 gallons of water to print one yard of fabric on atbed screens.With digital printing, we use only four gallons of water. Change can be challenging, but rewarding.

QT Fabrics has been printing digital fabrics in limited fashion since 2013, and we were the first fabric supplier to move new lines completely to digital in June 2018.The ability to transform art to fabric with minimal interpretations led us down this path.We needed to revamp our entire business model to meet this print method. Lots of internal education and communication with different factories was a big challenge.We want to share with you the process of fabric creation selling in your shops. Change is an evolutionary experience, but learning is always good.

We thank all the contributors and AQR team, and we all look forward to the future of fabric.

Ken Gamache, QT Fabrics

Table of Contents

- 200+ Years of QT Fabric Printing: Stroll through the timeline of fabric printing history.

- Sunny Days: Learn how this small-town quilt shop makes a big impact with digital fabrics in its business.

- Stroke of Luck: Artist Oclla Mason is enjoying how digital printing is allowing her unique style of artwork to come alive on fabric.

- Put Fabric to the Test: A series of tests assures fabrics are ready to be sewn into beautiful quilts.

- Finish Strong: You’ll sleep well at night knowing your quilt top will look great when machine-quilted.

- From the Artist’s Point of View: Dan Morris shares his thoughts on the growing popularity of digitally printed fabric.

- Move Your Business Forward: Marketing tips from a designer and shop owner are sage advice for improving your business.

- Just for You: Learn how custom digital printing can set your business apart.